|

INTRODUCTION PART ONE MAXIMILIAN BORHO Our story begins with Maximilian Borho, without whom there would be no story. Max was born in Neuburg an der Donau (Danube) on May 22, 1840. Max's father, Joseph Borr(ho), was a steingut worker, and his mother, Catharina Margaretha, was the daughter of a porcelain painter from Regensburg named Maier. Max probably had an extensive apprenticeship in the steingut industry, possibly with Dorfner. Max married one Catharina Geier of Duesseldorf. Soon afterward, in 1868, they moved to Cologne where their eldest son was born, and the following year found them in Höhr. Two of their children were born in Höhr; Helena in 1869, and Willhelm Otto in 1870. It is from the children's baptismal records that we know he listed his occupation as that of a modelleur. Over the next five years Max worked in Höhr and Grenzhausen, but in 1874 we find Max in Regensburg looking for partners to help him establish a steinzeug factory. Max brought with him the plaster mold techniques he had learned in Höhr, as well as design elements from both the Reinhold Hanke, and Merkelbach & Wick factories. It is very likely that he learned the manufacture, and use, of plaster molds from Reinhold Hanke himself, and he probably designed products for both Hanke, and Merkelbach & Wick. When Max arrived in Regensburg he represented himself as a "Fabricant" (Manufacturer), a "Mitbegrunder" (Co-founder), and a "Modelleur" (Designer). Although there is no record of his having been a manufacturer, or a co-founder, until he co-founded the Regensburg and Freising factories, Max surely had letters of introduction to back up his claims. In an area totally devoid of the proper clay, Max was able to convince two men, to become his partners in the stoneware factory. In order to do this, Max must have come armed with more than letters of introduction, he had to have been carrying guarantees of a continuing supply of Westerwald clay. Based on the way events played out, I believe Max was in Regensburg as an agent of Reinhold Hanke, who may have personally guaranteed the continuing supply of clay. His partners were August Zinkl and Rudolf Thaller, who was Zinklís brother-in-law. The company was called "Borho, Zinkl and Co." Then, in 1875, after only 13 months, Max sold his share in the factory to Gustav Freidrich "Fritz" Thenn, and moved on to Freising. On January 1, 1876 Max established yet another stoneware factory, this time in Freising, with a new partner, Adam Schön. Freising is about 30km NNE of Munich, again in an area devoid of the proper clay. The company was called "Schön and Borho" but no records exist confirming that Max was ever a partner. In less than 10 months Max had sold his interest in the company to Albert Hauber and quietly disappeared from the world stage. It seemed strange to me that Max Borho would found two steinzeug factories, and then once they were operational, sell his interest in them, unless his purpose was not to manufacture steinzeug but to create a market for Westerwald clay. Let us suppose for a minute that Reinhold Hanke, through either purchase, lease, or his wife's family, controlled large deposits of Westerwald clay, more than he could use for his own purposes. Hanke's wife Maria-Josefa Krebs was from a family that had been in the steinzeug business since 1841, and had factories in Valendar and Höhr. Let us also suppose that the Hanke factory was already at maximum output with no letup of demand in the foreseeable future. How do you profit from this growing market if your factory is already at maximum output, and you want to do it without further capital expenditure? Well, if you had a market for the clay you controlled, you could literally profit from every piece of steinzeug manufactured by your competitors/customers. And finally let us suppose that Hanke began to train competitor/customers who, because of the demand for steinzeug, would be no threat to his business, but would become customers for the clay he controlled. In 1874 we find Max Borho, possibly an ex Hanke employee, on his way to found the Regensburg and Freising factories, and in 1883 Peter Dümler, who had apprenticed with Hanke, joined his brother-in-law Albert Breiden in founding Dümler & Breiden. Customers all? Well it is one possible scenario. There is one more reason to suspect Reinhold Hanke's involvement in the establishment of both the Regensburg and Freising factories, and that is the difficulty in identifying which of the factories manufactured certain "altdeutsch" (Old German) style pieces. Max Borho had possibly been a modelleur for Hanke, and when he established the Regensburg and Freising factories he used many of the same decorative stamps, roll stamps and applique molds that had been used by the Hanke factory. Did these stamps and molds belong to Borho or Hanke? Did Borho remove them from the Hanke factory without Hanke's permission, or did Hanke suggest that Borho take them to ease the establishment of the new factories? However it actually played out, reasons to suspect a link between Reinhold Hanke and the Regensburg and Freising factories refuse to go away. Even the death of Reinhold Hanke in June of 1886 coincides with the closing of the Thenn factory in Regensburg and the end of steinzeug production by HR in Freising. ~~~~~~~

PART TWO SOME FACTS THAT NEED SORTING Since 1993 I've been acquiring steins I knew were from the Borho-Zinkl, Fritz Thenn, Regensburg factory, and another group that I suspected, and later knew, were from the Freising factory, but I had nothing to actually connect them to that factory until recently. Hopefully, the evidence I present will convince you, as it did me, that the Freising factory not only manufactured steins as HR, but also prior to becoming HR, and that they manufactured for others as well as themselves. My intention is to use recent discoveries, and a different turn of thought, to build upon and expand, what Mike Wald started well over twenty years ago. You will find that I repeat a number of points throughout the course of this work, and that is not without purpose, repetition being an excellent pathway to understanding. The Freising factory was productive from 1876 to at least 1907, but little in the way of factory history has survived the intervening years. According to Mike's HR book, Roland Henschen made a trip to Freising in the mid to late 1970s in an attempt to collect information on the HR factory and came away empty handed. Roland found that all factory operational records had either been lost or destroyed. Neither have any sales catalogs surfaced, of which there must have been several. Therefore, until such time as any documentation might surface, all conclusions concerning the Freising/HR factory must remain theory. On the other hand, if we have to wait for proof positive before we publish anything, nothing may ever get published. The probability of any documentation surfacing at this late date is not impossible, but unlikely, and because this information is long overdue, I am publishing my conclusions based wholly on those facts we do have. Doing research is often like assembling an old jigsaw puzzle purchased at a yard sale. You take it home, put it together, and only then, find that there are a number of pieces missing. In research the pieces are facts, and in any given research project more than a few facts may be missing. Sometimes missing pieces can be deduced from the surrounding data because logic, and experience, suggest what the missing pieces should look like, and once we have some idea of what we're looking for, we can actively seek it out. The future may prove us wrong, if indeed evidence to the contrary eventually surfaces, but until that happens we should consider ourselves on reasonably solid ground if the conclusions fit the known facts. For the present, most of the pieces seem to fit and from my point of view form a fairly complete picture, but there are still some pieces missing, and others that I am in posession of, but have yet to fit into their proper places. Here are the facts I had to work with. FACT I.: About the same time that Roland Henschen was in Freising, Werner Sahm came up with an advertisement that appeared in the official catalog published by the Bavarian Arts & Crafts Museum of Nurnberg in 1882, which reads: "Hauber & Reuther, Stoneware Factory, Freising, Established 1876. Specialty: Beer Services. 20 male and 10 female workers. Consumes about 1,200 Zentner of clay annually, from the Rhine region. Markets in Germany, Austria and Switzerland, Belgium and England. Received 1876 prize diploma in Munich." Author's note: (1 Zentner = a hundredweight, or 50 kilos) That statement tells us a great deal, unfortunately part of it is misleading. It suggests that the Hauber & Reuther factory was established in 1876, when actually, it didn't become Hauber & Reuther until around 1882. The 1876 date refers to the founding of the Freising factory, but back then it was the Schön-Borho Co..

FACT II.: In 1877 the Freising factory received some negative press. Shortly after the 1876 German Arts and Crafts Exhibit in Munich there were published reports that both the Regensburg factory of Zinkl-Thenn, and the Freising factory of Schön-Hauber, produced wares inferior to those of Merkelbach & Wick of Grenzhausen. Among other things, this fact tells us that in less than one year, the factory ownership had changed from "Schön-Borho," to "Schön-Hauber." We know this from the published reports below.

This criticism is obviously the result of regional pride, and in the over all scheme of things should have caused little or no concern simply because Merkelbach & Wick's product was superior not only to that of the Regensburg and Freising factories, but to nearly ALL other factories of the time. For some examples of Merkelbach & Wick steins, CLICK HERE. However, the criticism was taken to heart, and as a result, I believe a number of "altdeutsch" (Old German) style pieces were dropped from production, and the character steins, even though they are not specifically mentioned in the above criticism, were redesigned to bring them more in line with those made by other factories. Later events suggest that the pieces in question, already in inventory, were pulled and placed in storage.

FACT III.: Is that even though the firm had taken out a listing in the "Ceramics Address Book" for 1887, Fritz Thenn closed the doors to his Regensburg factory for good in 1886. FACT IV.: Is that with the golden age of stein making in full bloom, stoneware production in Freising also came to an end in 1886. FACT V.: Is that Reinhold Hanke passed away on June 22, 1886. I believe that facts, III, IV and V, are closely linked. FACT VI.: Is the "Merchandising Marks Act of 1887." This act required that all German manufactured products, made for export, be marked "Germany," or "Made in Germany." This, along with the last three facts, provides a convenient, and coincidental, line of demarcation.

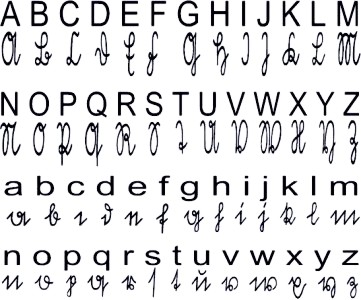

FACT VII.: Is that there were economic and political factors at work during the mid to late 1880s that played a part in what happened at the Regensburg and Freising factories. Wages were on the rise, countries to which they exported their wares began to charge import duties, there were too many steinzeug factories in operation and the supply had outstripped the demand. Records from the Fritz Thenn factory in Regensburg show that business had declined and workers were in danger of being let go. The factories in the Westerwald were probably facing the same issues. Some factories had to go and the Bavarian factories might well have been that something. Reinhold Hanke's death provided a convenient out and the clay supplies to Regensburg and Freising were cut off causing Fritz Thenn to close his factory for good and the Hauber & Reuther factory to convert their production from steinzeug to porcelain. FACT VIII.: Is, that there were thousands of ceramic shards recovered from two digs in Freising, in 1988, and 1990. These digs excavated two dumps associated with the Freising factory. Among the shards recovered, in addition to fragments of steins, punch bowls, plaques, candle holders, etc., were pieces of spacer capsules. These spacers are used to allow proper heat, and glaze, distribution throughout the kiln. The recovered capsules and other firing aids are salt glazed, and by themselves are evidence of saltglazed stoneware production in Freising. Additionally, analysis shows that the capsules and firing aids were made from a local clay, higher in sand content than the Westerwald clay used for production. That way none of the imported clay needed to be wasted for throw away items. FACT IX.: It is generally accepted that there is a 99% plus probability, that shards found in wasting-heaps, on property where there was a kiln in operation, are products of that kiln. FACT X.: Is that capacity marks appear to be unique to any given factory. Because of that, we can not only show that HR steins were produced in Freising, but that two other factories also produced steins for HR. FACT XI.: Is that because of the previous fact we can also show that prior to 1886 the Freising factory produced steins for at least three other marks, in addition to their own HR mark. FACT XII.: According to the 1890 "Ceramics Address Book," Hauber & Reuther had salesmen and showrooms in Berlin, Hamburg, Paris, Amsterdam and London, as well as a permanent booth (number 69) at the Leipzig Fair. FACT XIII.: Is that between 1898 and 1907, Hauber & Reuther purchased steins from A. J. Thewalt. FACT XIV.: Is that the latest date we have for HR actually doing business is 1907. Roland Henschen found copies of ceramic industry advertisements for Hauber and Reuther, of Freising (Bavaria), in the 1907 "Ceramics Address Book." FACT XV.: Is that Albert Hauber, who now had a business in Munich, sold the idle factory and property to Josef and Else Senger on May 27, 1910, for 15,000 Marks. Many of the things you will read here will not be new. I have taken already discovered facts, along with some new material, and reordered them into a workable solution. They just had to be sorted, and then assembled into a picture that made sense. Because of that, my conclusions may differ from those of the original authors. We must now take these facts, and clues, along with the physical evidence (the steins and their marks), and build our case. Before we get too far into this I need to define the terms I am using, so we are all on the same page. The terms in BOLD letters are the ones I use throughout this work. ~~~~~~~ The following chart, showing hand written script as it was written prior to WW II, can be used to decypher the decorator initials found on steins manufactured in Freising.  ~~~~~~~ |